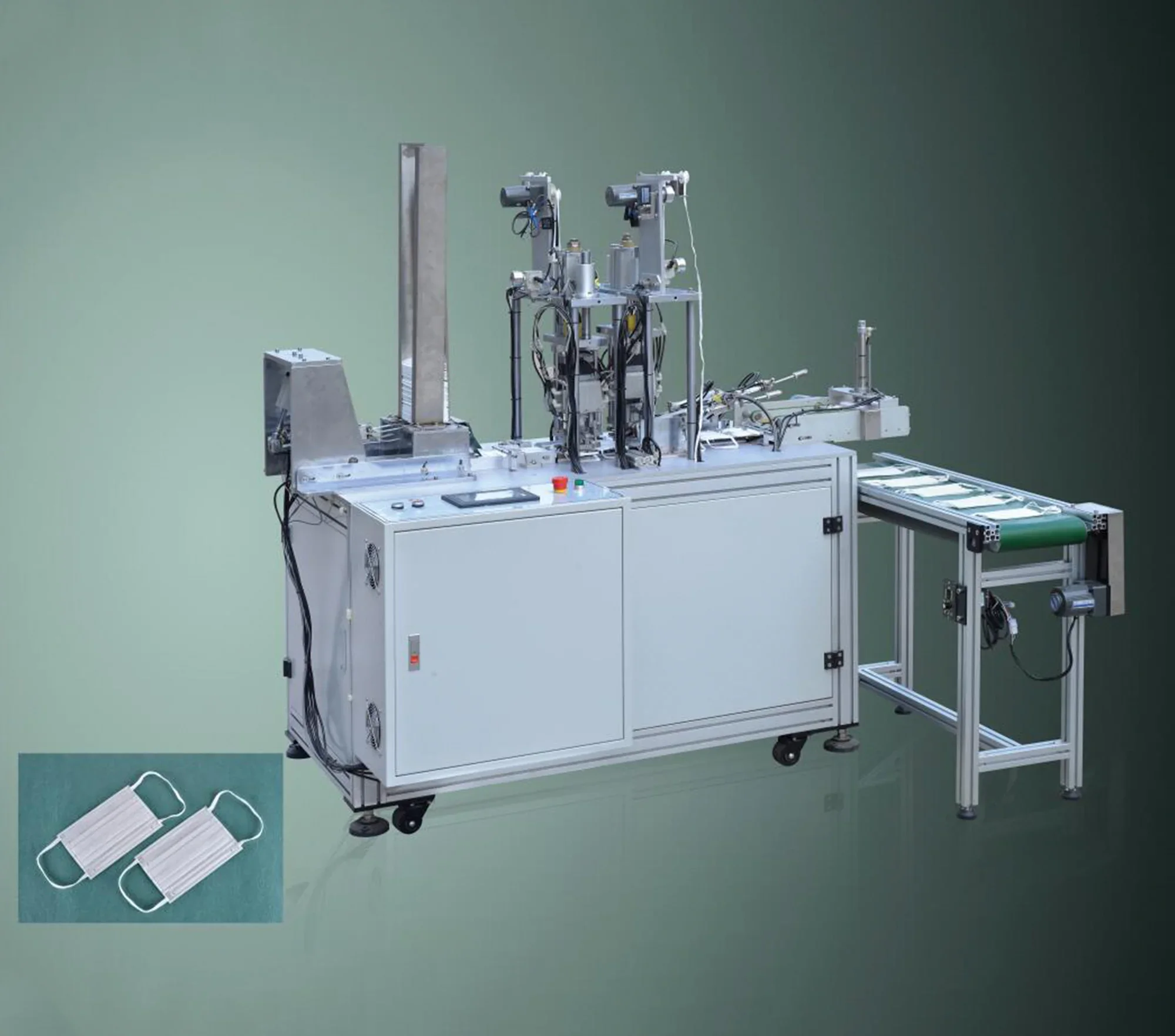

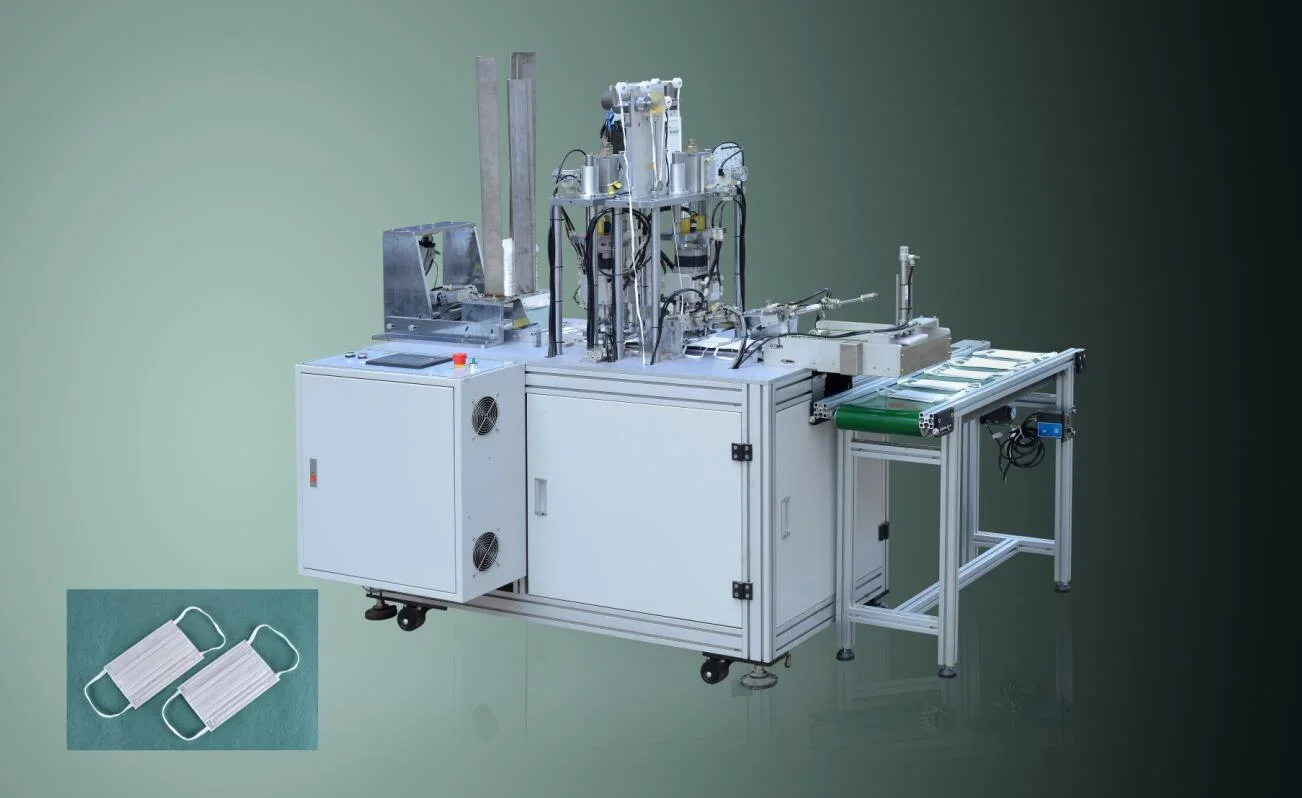

In the competitive landscape of manufacturing, achieving optimal efficiency and quality is essential, particularly in the production of critical items like face masks. As manufacturers strive to enhance their production capabilities, they face numerous challenges, especially in the sealing process that ensures masks provide reliable protection. To address these challenges, auto-feeding mask sealing machine have emerged as a groundbreaking solution. These advanced machines automate the feeding of materials into production lines, significantly improving workflow and consistency in mask sealing operations. This article will explore how auto-feeding machines can effectively tackle the complexities of mask sealing, highlighting their innovative features and the substantial benefits they offer to manufacturers aiming for excellence in production quality.

Understanding the Mask Production Process

The production of face masks involves several critical steps that must be executed with precision to ensure a high-quality final product. The main stages include:

Material Preparation: The process begins with sourcing high-quality materials, such as non-woven fabrics and filter layers, which are essential for effective filtration.

Mask Forming: The raw materials are then shaped into mask forms using specialized machinery that folds and cuts the fabric to the required dimensions.

Sealing: This crucial step involves sealing the edges of the masks using methods such as ultrasonic welding or heat sealing to create airtight seals.

Quality Control: After sealing, each mask undergoes rigorous quality checks to ensure it meets safety and performance standards.

Packaging: Finally, the finished masks are packaged for distribution, ensuring they remain uncontaminated until they reach consumers.

The Role of Auto-Feeding Machines

Auto-feeding machines play a vital role in streamlining the material handling process during mask production. By automating the feeding of raw materials into the production line, these machines reduce manual labor and enhance overall efficiency.

Key Features of Auto-Feeding Machines

Auto-feeding machines come equipped with a range of features designed to optimize their performance:

High-Speed Feeding: Capable of processing large volumes of materials quickly, these machines help maintain high production rates without compromising quality.

Precision Alignment: Advanced sensors ensure that materials are fed accurately into the production line, reducing errors and improving seal quality.

Integration with Existing Systems: Auto-feeding machines can be easily integrated into existing production lines, enhancing workflow without requiring extensive modifications.

Benefits of Using Auto-Feeding Machines

The implementation of auto-feeding machines in mask production offers numerous advantages that directly address common challenges:

1. Enhanced Production Efficiency

By automating the feeding process, manufacturers can significantly reduce downtime associated with manual loading. Auto-feeding machines allow for continuous operation, enabling higher output rates and meeting increased demand without sacrificing quality.

2. Improved Sealing Consistency

Auto-feeders ensure that materials are fed uniformly into the sealing machine, which helps maintain consistent tension and alignment. This uniformity is crucial for achieving high-quality seals that meet safety standards.

3. Cost Reduction

With reduced reliance on manual labor for feeding materials, manufacturers can lower labor costs while reallocating human resources to more value-added tasks such as quality control and maintenance.

4. Reduced Material Waste

Manual feeding processes often result in material waste due to misalignment or improper handling. Auto-feeding machines minimize these risks by ensuring precise material placement, thereby reducing waste and improving overall yield.

5. Enhanced Worker Safety

Automating the feeding process reduces the physical strain on workers associated with manual handling of materials. This not only improves workplace safety but also enhances employee satisfaction by minimizing repetitive tasks.

Addressing Mask Sealing Challenges

The sealing process is critical in ensuring that masks provide adequate protection. Auto-feeding machines contribute to overcoming common sealing challenges:

1. Consistency in Sealing Quality

One of the primary challenges in mask production is achieving consistent sealing across all units. Variations in material tension or alignment can lead to weak seals that compromise mask integrity. Auto-feeders ensure that materials are fed uniformly, which helps maintain consistent tension during sealing.

2. Speed vs. Quality Trade-off

Manufacturers often face a dilemma between increasing production speed and maintaining quality standards. Auto-feeding machines allow for high-speed operation while still ensuring that each mask is properly aligned and sealed, thus eliminating this trade-off.

3. Reducing Material Waste

Improperly fed materials can lead to significant waste during production. By utilizing auto-feeding technology, manufacturers can minimize waste generated from misaligned or damaged materials during the feeding stage.

Future Trends in Auto-Feeding Technology

As technology continues to evolve, so too will auto-feeding machines for mask production:

1. Sustainable Practices

With growing concerns about environmental impact, future auto-feeding systems may incorporate eco-friendly materials and processes designed to minimize waste and energy consumption during production.

3. Modular Designs

Modular designs will allow manufacturers to customize their auto-feeding systems according to specific needs, making it easier to scale operations up or down based on market demand.

Conclusion

Auto-feeding machines represent a transformative solution for addressing the challenges associated with mask sealing and packaging processes. By enhancing efficiency, reducing costs, improving quality control, and ensuring worker safety, these machines play a vital role in modernizing mask production lines.

Broadfair Automation Equipment Co., Ltd.'s commitment to innovation positions it at the forefront of this industry transformation. As demand for face masks continues globally, leveraging advanced automation technologies like auto-feeders will be essential for manufacturers striving to meet market needs while maintaining high standards of quality and safety.

In summary, adopting auto-feeding solutions not only optimizes production but also enhances the overall reliability of mask manufacturing processes—ensuring that we can meet health demands effectively while safeguarding public health through quality protective equipment.