Circulating fluidized-bed (CFB) technology has become a crucial component in the chemical and petrochemical industries, offering enhanced efficiency, sustainability, and versatility in various applications. This blog explores the role of CFB units, their benefits, and how companies Chem-Unit are contributing to the advancement of this technology.

Understanding Circulating Fluidized-Bed Technology

A circulating fluidized-bed unit operates by suspending solid particles in an upward gas or air flow, creating a fluid-like motion. This technology is widely used in combustion, catalytic cracking, and gasification processes due to its superior heat and mass transfer capabilities.

Key Applications in the Chemical and Petrochemical Industries

Catalytic Cracking: CFB units are widely used in fluid catalytic cracking (FCC) to break down heavy hydrocarbons into valuable lighter products like gasoline and olefins.

Gasification Processes: CFB technology enables efficient gasification of solid fuels, converting biomass, coal, and waste materials into synthesis gas (syngas) for further industrial use.

Chemical Reactions: CFB reactors provide excellent mixing and heat transfer, making them ideal for large-scale chemical synthesis, including polymerization and specialty chemical production.

Environmental Applications: CFB scrubbers help remove sulfur dioxide (SO₂) and nitrogen oxides (NOₓ) from industrial emissions, improving environmental sustainability.

Advantages of Circulating Fluidized-Bed Units

High Efficiency: The continuous circulation of particles ensures improved heat and mass transfer, leading to more efficient reactions.

Fuel Flexibility: CFB systems can process a wide range of feedstocks, from fossil fuels to biomass and waste-derived materials.

Lower Emissions: Compared to conventional combustion methods, CFB technology produces fewer pollutants, contributing to cleaner industrial operations.

Scalability: These units can be designed for small-scale pilot testing as well as full-scale industrial production.

Chem-Unit: Advancing Fluidized-Bed Technology

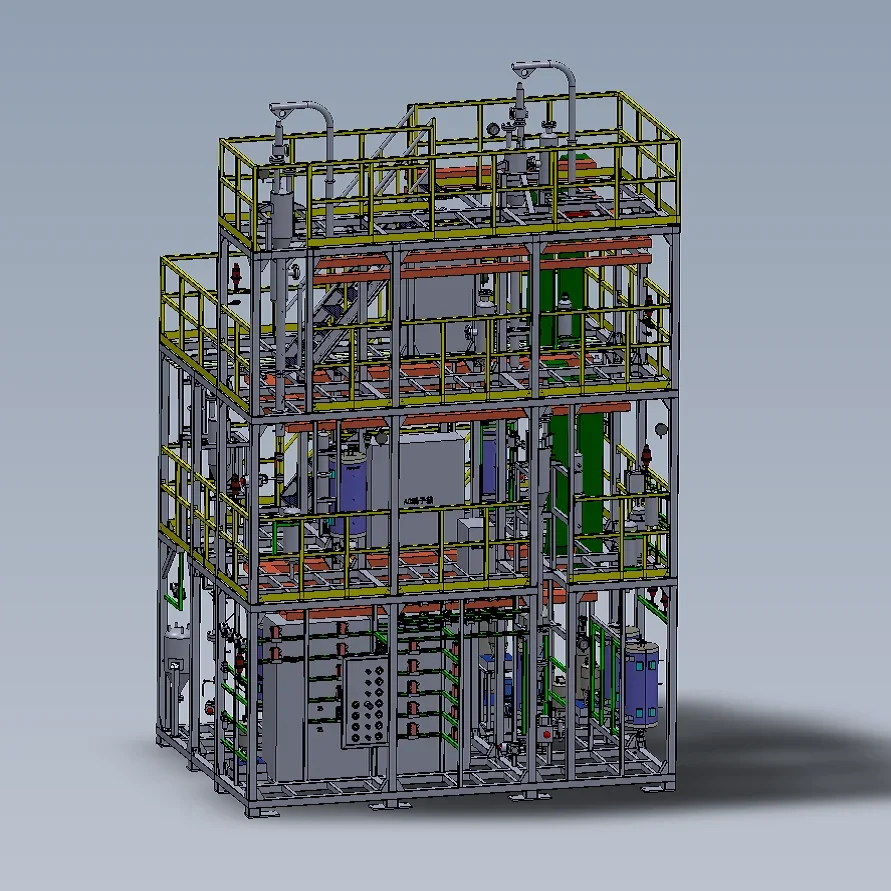

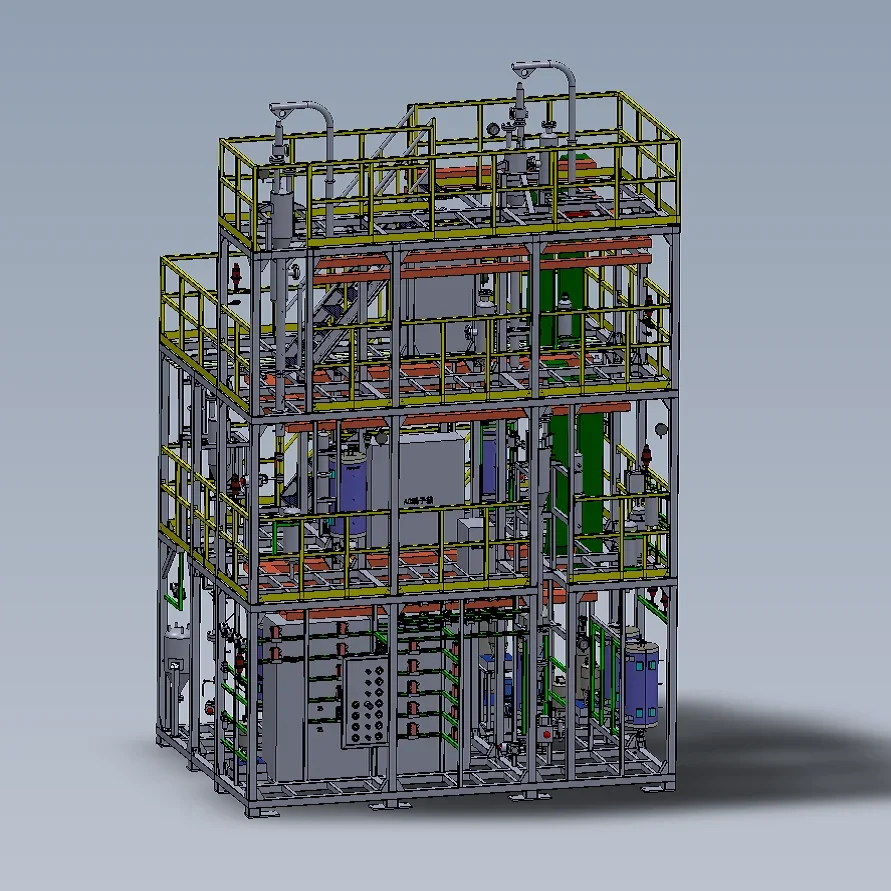

Chem-Unit is a leading company specializing in the research, design, manufacturing, and sales of modular experimental devices, pilot plants, production equipment, and robotic systems for chemical research and industrial applications. By leveraging cutting-edge CFB technology, Chem-Unit provides innovative solutions for:

Pilot and Mid-Scale Testing: Offering customized CFB units for experimental and pre-commercial testing.

Industrial Production: Designing and manufacturing CFB systems for full-scale chemical and petrochemical operations.

Automation and Robotics: Integrating automated solutions to enhance process efficiency and reduce human intervention in hazardous environments.

Conclusion

Circulating fluidized-bed units play a vital role in the chemical and petrochemical industries, enhancing efficiency, sustainability, and process flexibility. Companies like Chem-Unit are at the forefront of innovation, driving advancements in CFB technology for a wide range of applications. As the industry continues to evolve, the adoption of CFB technology will contribute to cleaner and more efficient industrial processes.

Exploring the Benefits of Circulating Fluidized-Bed Units in Energy Production