In the realm of construction machinery, the hydraulic slewing drive plays a pivotal role in enabling equipment to rotate and position itself accurately. From excavators to cranes, the efficiency and reliability of these drives directly impact the productivity and operational costs of construction projects. Among the many manufacturers that provide such drive equipment, Wuxi UpperPeak Drive Equipment stands out for its high-quality products and advanced technology. Wuxi UpperPeak Drive Equipment focuses on the research and development and production of various types of hydraulic transmission equipment, which not only meets the market's demand for efficient, stable and durable drive solutions, but also reflects the company's unremitting pursuit of technological innovation and product quality. Through continuous technological research and development and market expansion, Wuxi UpperPeak Drive Equipment is gradually becoming a leader in the industry, providing high-quality hydraulic transmission equipment and services to customers around the world.

Enhanced Hydraulic System Efficiency

One of the core focus areas in performance optimization is enhancing the hydraulic system's efficiency. This involves refining fluid flow dynamics and pressure management to minimize energy loss and maximize torque output. Advanced valve designs, such as proportional and servo valves, enable more precise control over fluid flow, reducing spillage and pressure drops. Furthermore, the integration of variable displacement pumps allows for dynamic adjustment of flow rates based on real-time demand, thus optimizing energy consumption.

By implementing closed-loop control systems, manufacturers can achieve tighter regulation of pressure and flow, leading to smoother slewing operations and reduced wear and tear on components. These advancements not only boost the drive's efficiency but also contribute to lower operational noise levels and extended component lifespan.

Advanced Material and Component Design

Material science advancements have significantly contributed to the performance optimization of hydraulic slewing drives. High-strength steels and composite materials are now being utilized to create lighter yet more durable components. These materials enhance the drive's structural integrity, enabling it to withstand the rigorous demands of construction environments without compromising on reliability.

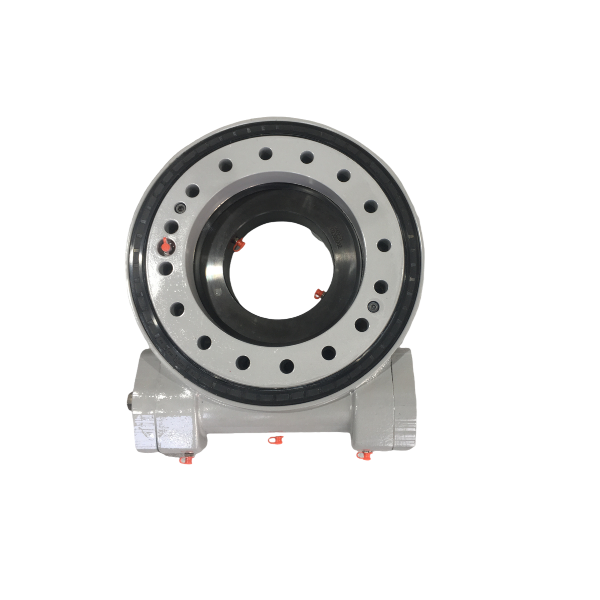

Innovations in gear and bearing designs further bolster durability. For instance, the adoption of spiral bevel gears with optimized tooth profiles reduces friction and wear, while precision bearings ensure accurate and stable rotation. These design enhancements translate into reduced maintenance intervals and increased uptime, directly benefiting construction project timelines.

Smart Sensors and Controls

The integration of smart sensors and Internet of Things (IoT) technology represents a transformative shift in the optimization of hydraulic slewing drives. These sensors continuously monitor key performance indicators such as temperature, pressure, vibration, and rotational speed, providing real-time data that can be analyzed to predict and preempt potential failures.

Predictive maintenance algorithms leverage this data to schedule maintenance activities before issues escalate, thereby minimizing downtime and preventing costly repairs. Additionally, remote monitoring capabilities enable operators and technicians to diagnose problems remotely, expediting the resolution process and enhancing overall equipment availability.

Energy Recovery and Regenerative Braking

Energy recovery and regenerative braking systems are emerging as critical components in the quest for more sustainable and energy-efficient hydraulic slewing drives. During deceleration or braking phases, these systems capture the kinetic energy that would otherwise be lost as heat and convert it back into usable hydraulic power.

By integrating accumulators or energy storage devices, this reclaimed energy can be reused to assist with acceleration or to power auxiliary functions, thereby reducing the overall energy consumption of the machinery. This not only aligns with the industry's shift towards more environmentally friendly practices but also contributes to cost savings by minimizing fuel or electric power requirements.

Conclusion

The performance optimization of Wuxi UpperPeak Drive Equipment hydraulic slewing drives in construction machinery is a multifaceted endeavor that spans enhanced hydraulic efficiency, advanced material science, smart technology integration, and energy recovery innovations. Each of these areas represents a significant leap forward, contributing to more reliable, efficient, and sustainable equipment.

By embracing these advancements, manufacturers and operators can expect to witness improved productivity, reduced operational costs, and a smaller environmental footprint. As the construction industry continues to evolve, the ongoing refinement of hydraulic slewing drive technology will be instrumental in driving innovation and meeting the demands of future projects. The journey towards ultimate performance optimization is ongoing, with each technological breakthrough paving the way for even greater achievements in the realm of construction machinery.