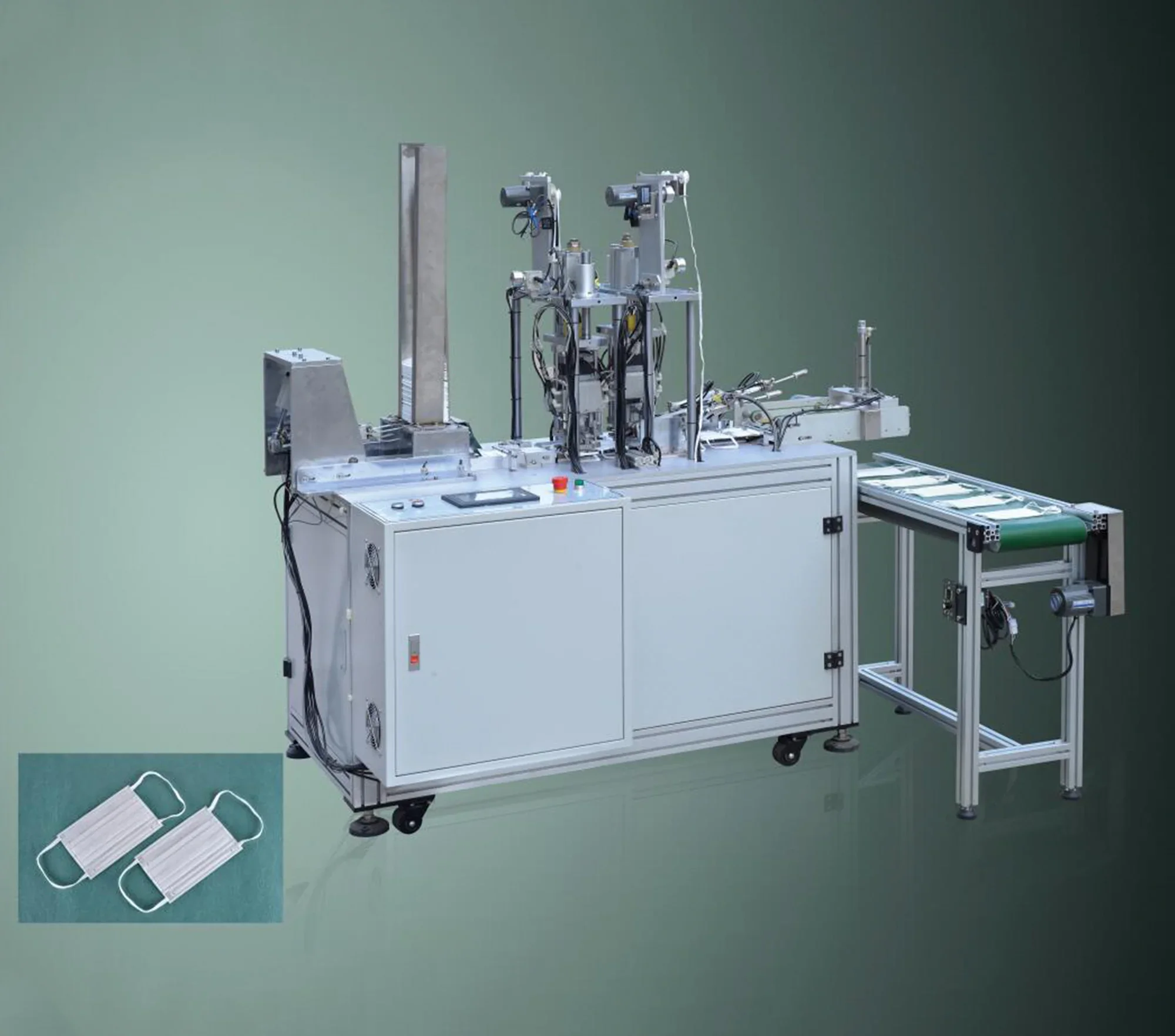

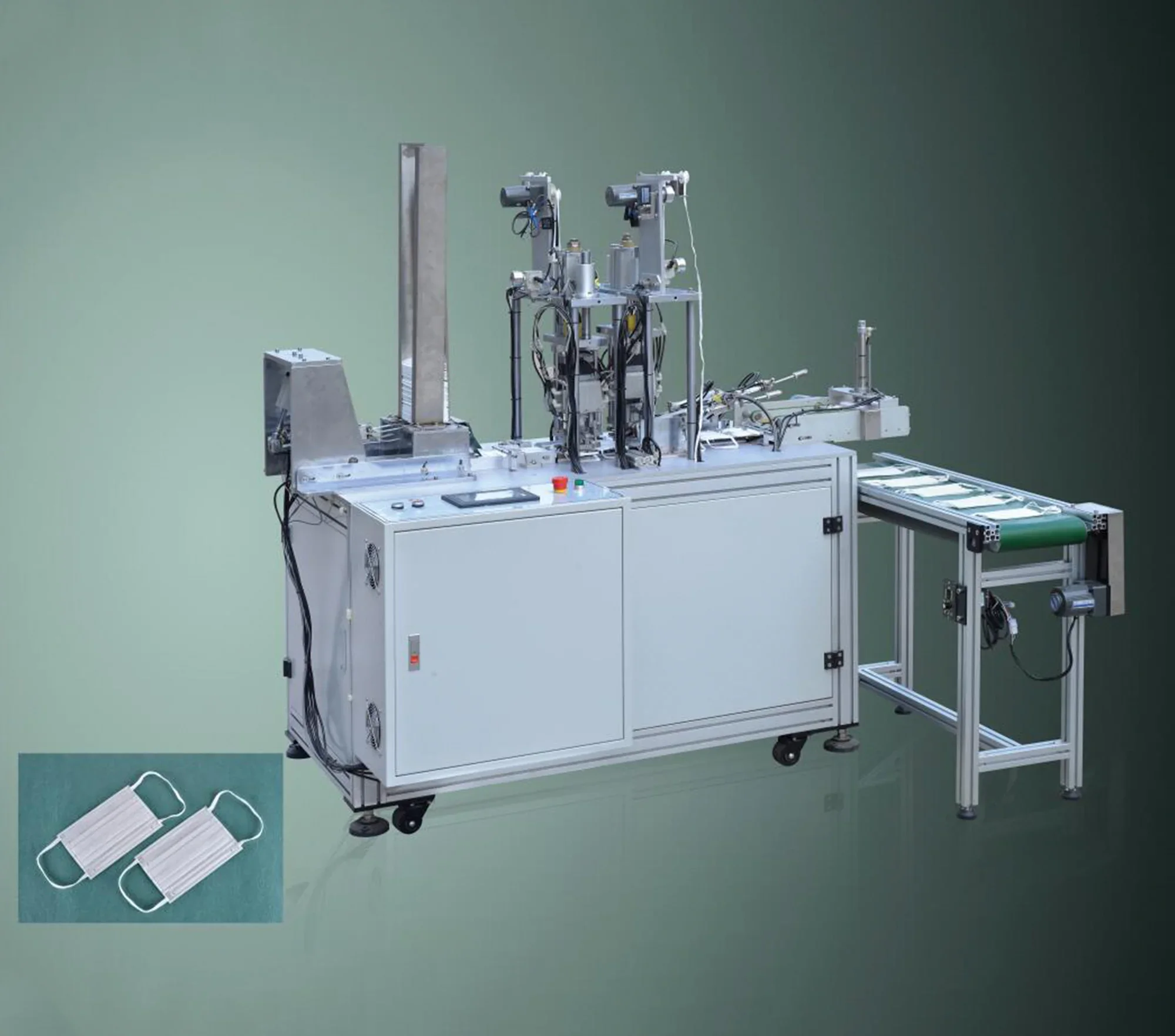

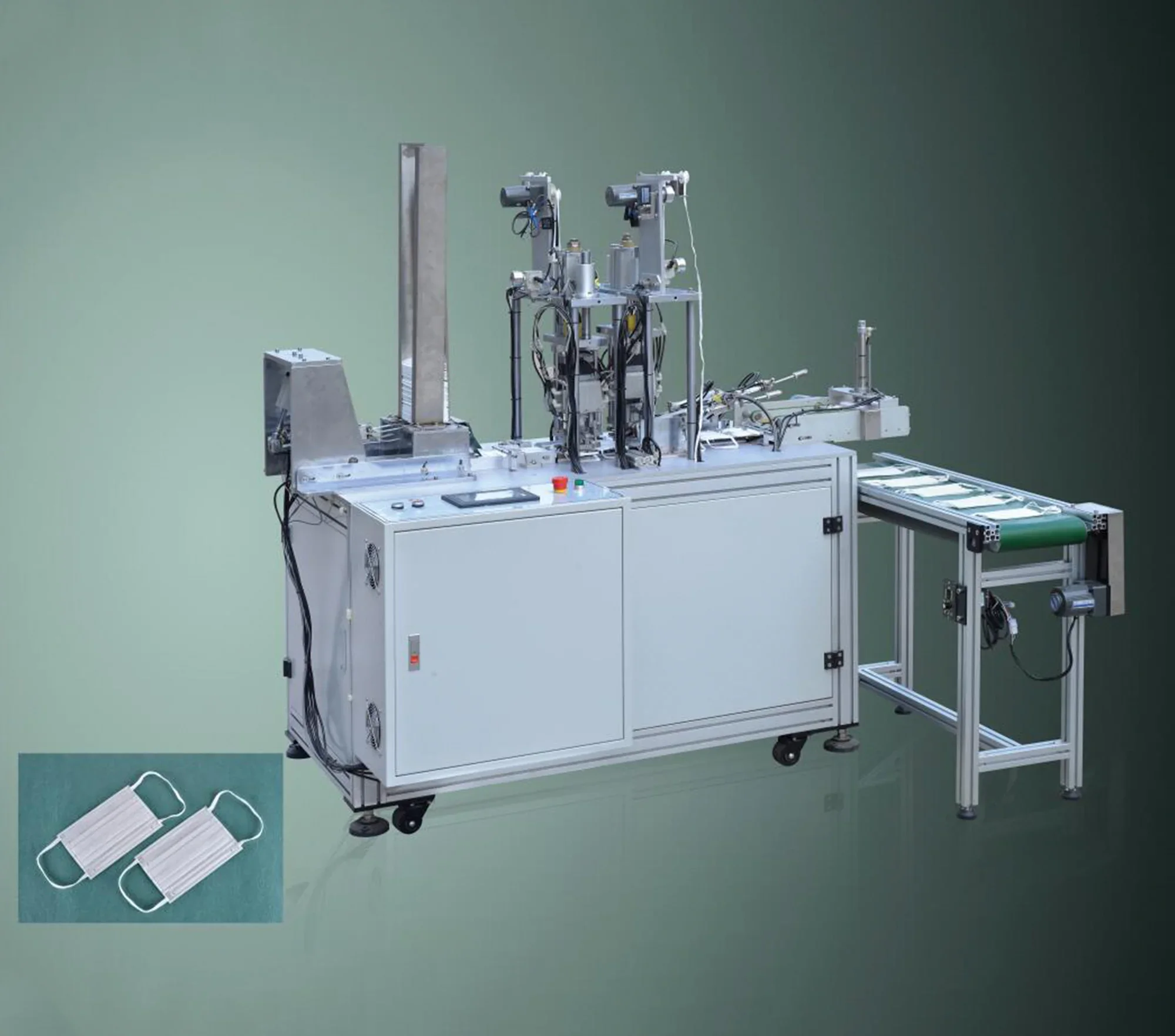

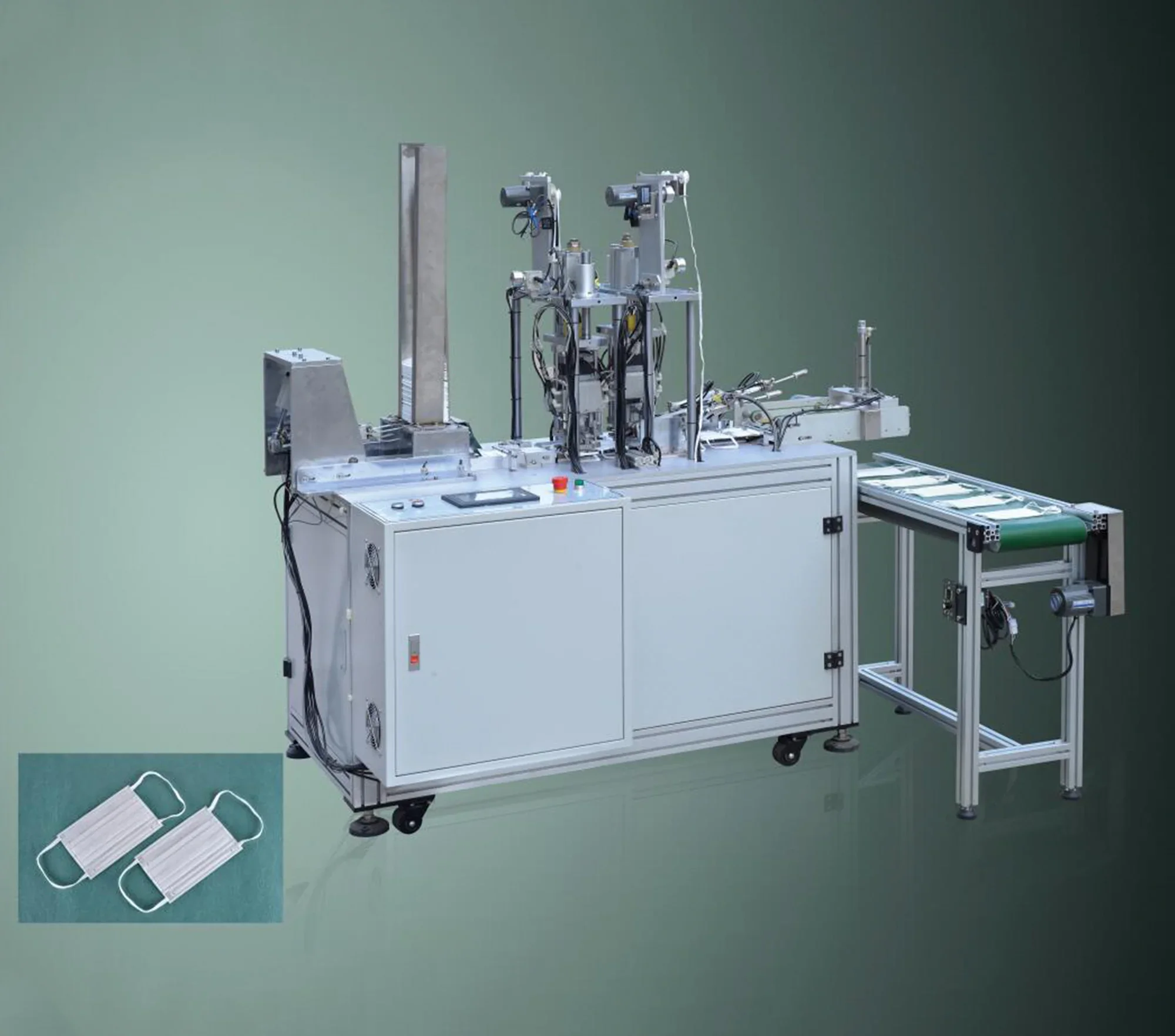

In the wake of increasing demand for personal protective equipment, particularly during health crises, the importance of efficient mask production has surged. Broadfair Automation Equipment Co., Ltd., a leading high-tech enterprise specializing in the design and manufacture of fully automatic mask machines, plays a pivotal role in this industry. Among the various innovations in mask manufacturing technology, auto-feeding mask sealing machines stand out as essential tools that enhance productivity and ensure quality. This comprehensive guide will delve into the workings, advantages, and considerations of auto-feeding mask sealing machines, providing valuable insights for manufacturers looking to optimize their operations.

Understanding Auto-Feeding Mask Sealing Machines

Auto-feeding mask sealing machines are automated systems designed to streamline the process of producing and packaging face masks. These machines not only seal masks but also incorporate feeding mechanisms that automatically supply masks into the sealing area, significantly reducing manual labor and increasing efficiency.

Key Components of Auto-Feeding Mask Sealing Machines

Feeding System: This component is responsible for automatically feeding masks into the sealing area. It can include various technologies such as conveyor belts, pick-and-place robots, or suction systems that ensure a steady flow of masks for processing.

Sealing Mechanism: The heart of the machine, this system uses heat or ultrasonic technology to seal the edges of the masks securely. The sealing process is crucial for ensuring that masks are airtight and effective.

Control System: Most modern machines are equipped with PLC (Programmable Logic Controller) systems that allow for precise control over various parameters such as speed, temperature, and sealing time. This automation enhances consistency and quality in production.

Quality Control Sensors: These sensors monitor the production process in real-time, detecting any defects or inconsistencies in the masks being produced. This feature helps maintain high standards and reduces waste.

Output Conveyor: After sealing, the finished masks are transported via an output conveyor to packaging stations or storage areas, ready for distribution.

Advantages of Auto-Feeding Mask Sealing Machines

1. Increased Production Efficiency

One of the most significant benefits of auto-feeding mask sealing machines is their ability to dramatically increase production efficiency. By automating the feeding and sealing processes, manufacturers can produce large quantities of masks in a shorter amount of time compared to manual methods.

High Throughput: These machines can operate at speeds ranging from 60 to 200 masks per minute, depending on the model and complexity of the masks being produced.

Reduced Labor Costs: With automation handling much of the work, companies can reduce their labor costs while reallocating human resources to other critical areas.

2. Consistent Quality Control

Quality is paramount in mask production, especially when it comes to medical-grade masks. Auto-feeding mask sealing machines are designed to ensure consistent quality throughout the manufacturing process.

Precision Sealing: The use of advanced sealing technologies ensures that every mask is sealed uniformly, minimizing the risk of defects.

Real-Time Monitoring: Integrated sensors provide continuous feedback on production quality, allowing for immediate adjustments if any issues arise.

3. Flexibility in Production

Modern auto-feeding mask sealing machines offer flexibility that allows manufacturers to adapt quickly to changing market demands.

Versatile Design: Many machines can be configured to produce different types of masks (e.g., surgical masks, N95 respirators) with minimal adjustments.

Adjustable Settings: Operators can easily change settings for speed, size, and sealing parameters without extensive downtime.

4. Enhanced Safety Features

Safety is a critical consideration in manufacturing environments. Auto-feeding mask sealing machines come equipped with numerous safety features designed to protect operators and ensure safe operation.

Emergency Stop Functions: These machines typically include emergency stop buttons that allow operators to halt operations immediately in case of an emergency.

Protective Shields: Many models feature safety shields that prevent accidental contact with moving parts during operation.

5. Improved Hygiene Standards

In an industry where hygiene is crucial, auto-feeding mask sealing machines help maintain high cleanliness standards throughout production.

Minimized Human Contact: Automated systems reduce human handling of masks during production, decreasing contamination risks.

Considerations When Choosing an Auto-Feeding Mask Sealing Machine

When selecting an auto-feeding mask sealing machine for your production line, several factors should be taken into account:

1. Production Capacity

Evaluate your production needs based on current market demands. Choose a machine with an output capacity that aligns with your expected volume to avoid bottlenecks in your operations.

2. Type of Masks Produced

Different types of masks may require specific features or configurations in a machine. Ensure that the model you choose is capable of producing the types of masks you intend to manufacture.

3. Space Requirements

Consider the physical footprint of the machine within your production facility. Ensure there is adequate space not only for the machine itself but also for surrounding equipment and personnel movement.

4. Maintenance and Support

Look for manufacturers who offer comprehensive support and maintenance services for their machines. Regular maintenance is essential for ensuring longevity and optimal performance.

Conclusion

Auto-feeding mask sealing machines represent a significant advancement in mask production technology, offering numerous advantages such as increased efficiency, consistent quality control, flexibility in production, enhanced safety features, and improved hygiene standards. As demand for face masks continues to grow globally, investing in these automated systems can provide manufacturers with a competitive edge in a rapidly evolving market.

Broadfair Automation Equipment Co., Ltd., as a leader in this field, is committed to delivering high-quality automatic mask machinery tailored to meet diverse production needs. By understanding the workings and benefits of auto-feeding mask sealing machines outlined in this guide, manufacturers can make informed decisions that enhance their operational capabilities while ensuring product integrity and safety in these challenging times.

From Manual to Automatic: The Advantages of the Auto-Feeding Mask Sealing Machine