High precision planetary reducers are essential components in the realm of automation, playing a critical role in various applications ranging from robotics to industrial machinery. Their unique design and functionality allow for efficient power transmission, precise motion control, and enhanced performance in automated systems. This article delves into the applications, advantages, and future prospects of high precision planetary reducers in the field of automation.

Understanding Planetary Reducers

What is a Planetary Reducer?

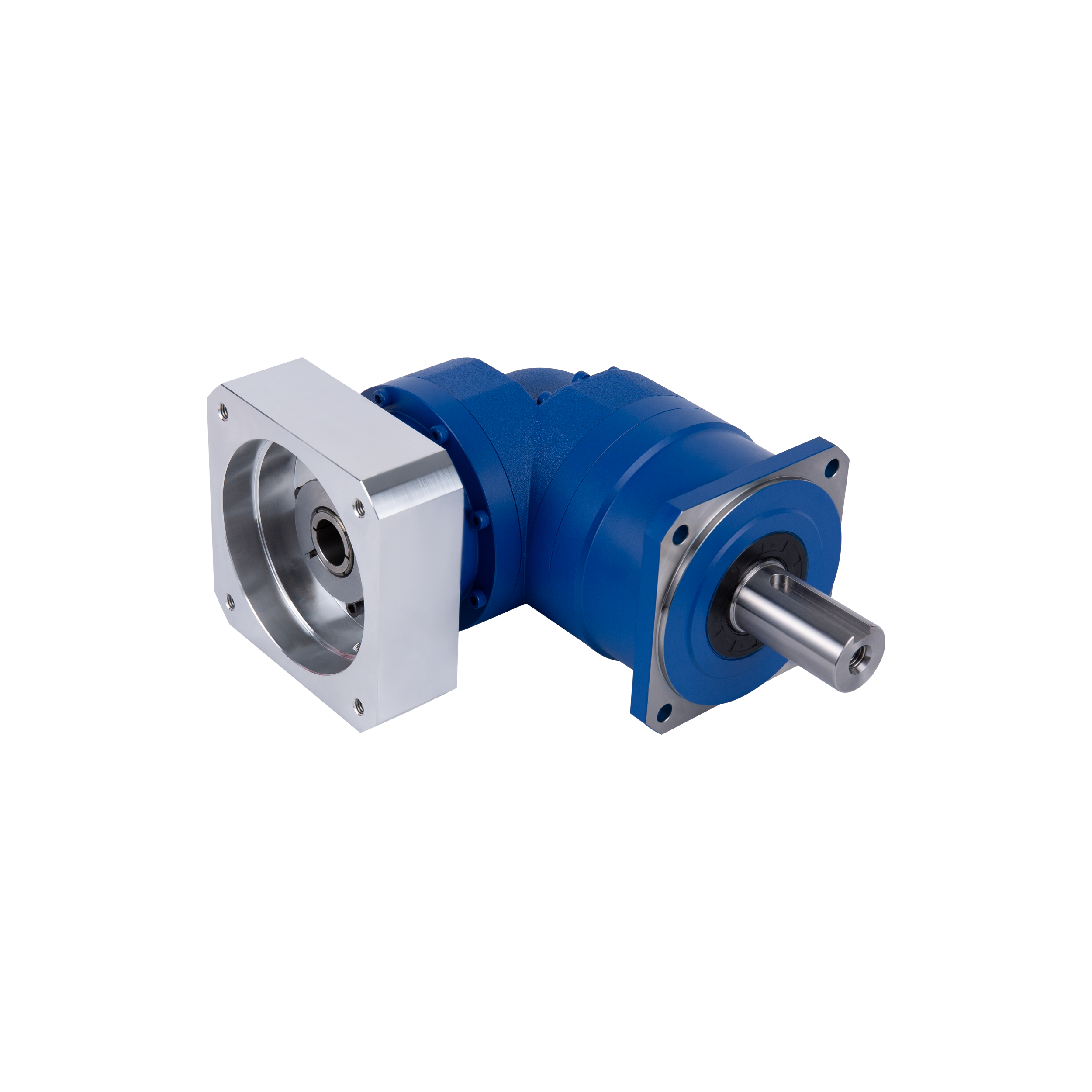

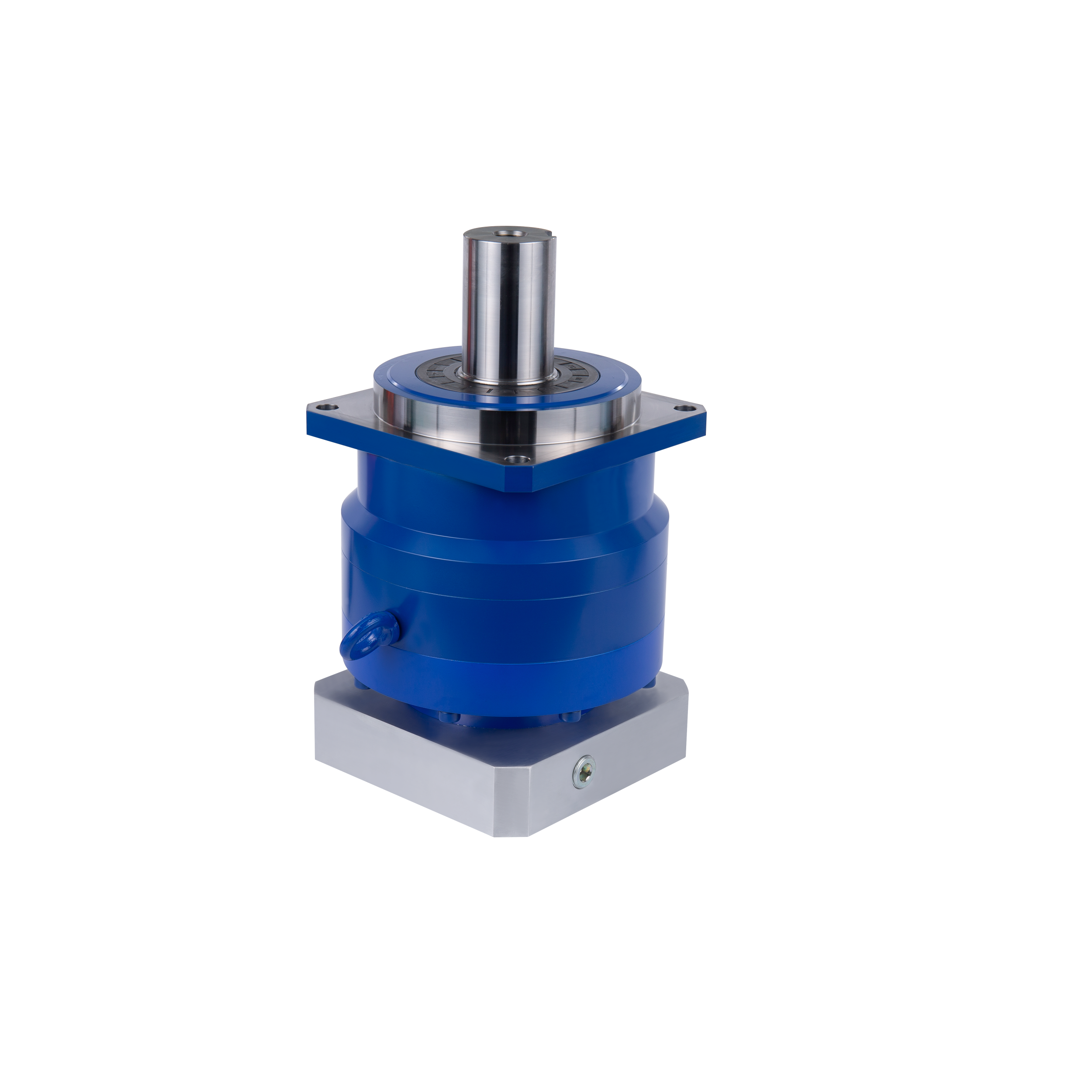

A planetary reducer is a gear mechanism that consists of a central sun gear, multiple planet gears, and an outer ring gear. This configuration allows for high torque transmission and compact design, making it ideal for applications requiring space efficiency and power density. The load is distributed among the planet gears, which reduces wear and increases durability.

Types of Planetary Reducers

Planetary reducers come in various types, including:

Single-stage planetary reducers: These provide moderate reduction ratios and are suitable for applications requiring lower torque.

Multi-stage planetary reducers: Offering higher reduction ratios, these are used in applications demanding greater torque and precision.

Applications in Automation

Robotics

High precision planetary reducers are widely used in robotics for their ability to provide accurate positioning and smooth motion control. They are essential in robotic arms, automated guided vehicles (AGVs), and collaborative robots (cobots). The low backlash characteristic of these reducers ensures that robotic movements are precise, enhancing the overall performance of automated systems.

CNC Machines

In computer numerical control (CNC) machines, high precision planetary reducers play a vital role in achieving the necessary accuracy for machining operations. They enable precise control over spindle speeds and feed rates, ensuring that components are manufactured to exact specifications. The efficiency of planetary reducers allows CNC machines to operate at higher speeds without compromising quality.

Material Handling Equipment

Planetary reducers are integral to material handling equipment such as conveyors, hoists, and lifts. Their robust design allows them to handle heavy loads while maintaining smooth operation. In automated warehouses, these reducers contribute to the efficiency of sorting systems and automated storage retrieval systems (AS/RS).

Advantages of High Precision Planetary Reducers

High Torque Capacity

One of the primary benefits of high precision planetary reducers is their ability to transmit high torque levels while maintaining compact dimensions. This feature makes them suitable for applications where space is limited but high performance is required.

Low Backlash

Low backlash is critical in applications requiring precise motion control. High precision planetary reducers are designed to minimize backlash, ensuring that positional accuracy is maintained even under varying load conditions.

Energy Efficiency

The design of planetary reducers allows for high transmission efficiency, often exceeding 95%. This efficiency translates into reduced energy consumption, making them an environmentally friendly choice for automation systems.

Future Trends in Automation with Planetary Reducers

Integration with Smart Technologies

As automation continues to evolve, the integration of smart technologies such as IoT (Internet of Things) will enhance the capabilities of high precision planetary reducers. These technologies will enable real-time monitoring and predictive maintenance, improving system reliability and reducing downtime.

Increased Demand for Custom Solutions

The growing complexity of automation systems will drive demand for customized planetary reducer solutions tailored to specific applications. Manufacturers will need to focus on developing adaptable designs that can meet diverse operational requirements across various industries.

Conclusion

High precision planetary reducers are indispensable components in modern automation systems, offering numerous advantages such as high torque capacity, low backlash, and energy efficiency. Their wide range of applications—from robotics to CNC machines—demonstrates their versatility and importance in enhancing operational performance.

As industries continue to embrace automation and smart technologies, the role of high precision planetary reducers will only become more significant. Companies like Yijiaang Automation Technology Co., Ltd., specializing in the development and production of these critical components, are well-positioned to meet the evolving needs of the market.

By understanding the benefits and applications of high precision planetary reducers, businesses can make informed decisions about their automation strategies—ultimately leading to improved productivity and competitiveness in an increasingly automated world. This exploration into high precision planetary reducers highlights their vital role within automation while emphasizing ongoing advancements that promise to shape their future applications across various industries.

The Role of High Precision Planetary Reducers in Industrial Automation