In the world of modern engineering and manufacturing, the reliability of a structure often begins with the quality of its components. One such essential component is the seamless cold drawn tube—a critical material known for its exceptional strength, precision, and surface finish. From industrial machinery and automotive parts to architectural frameworks and hydraulic systems, these tubes play a vital role in maintaining both structural integrity and aesthetic design.

As global demand for high-performance materials grows, companies like TORICH, a professional manufacturer and supplier of steel tube materials, are at the forefront of delivering precision-engineered tubing solutions to meet the needs of various industries.

What Are Seamless Cold Drawn Tubes?

Seamless cold drawn tubes are steel tubes that are produced without a welded seam, using a cold drawing process to refine the tube’s dimensions, surface finish, and mechanical properties. The process begins with a solid round billet that is pierced to form a hollow shell, then drawn through a die to achieve the final tube size. Unlike hot rolling, the cold drawing method occurs at room temperature, offering improved dimensional control and surface quality.

Key Characteristics of Seamless Cold Drawn Tubes

High Dimensional Accuracy

Cold drawn tubes boast tight tolerances in both outer diameter and wall thickness, ensuring compatibility with precision assembly and machining.

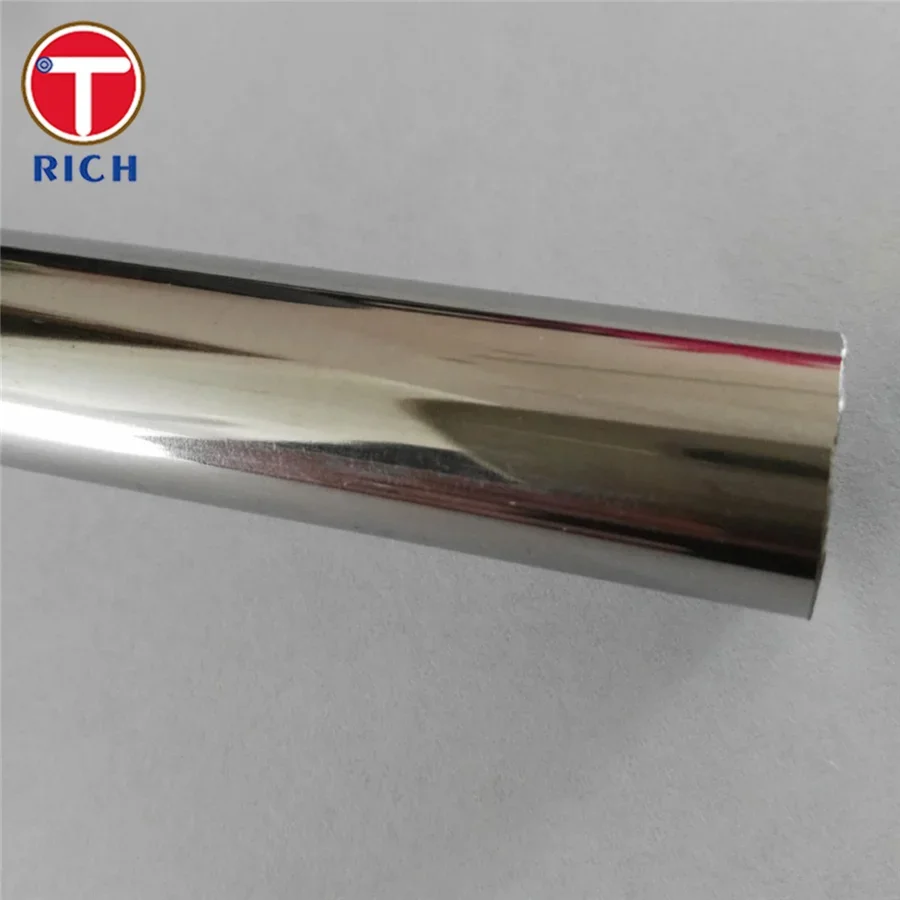

Smooth Surface Finish

The cold drawing process results in smooth inner and outer surfaces, which reduce friction and wear in applications like hydraulic cylinders and precision instruments.

Superior Mechanical Properties

The cold working process enhances yield strength, tensile strength, and hardness, making these tubes ideal for load-bearing and high-pressure applications.

No Weld Seams

Being seamless eliminates the potential weak point that exists in welded tubes, offering greater uniformity and reliability under stress.

Versatile Material Options

Seamless cold drawn tubes are available in carbon steel, alloy steel, and stainless steel, depending on the application requirements.

Applications Across Industries

Thanks to their strength and precision, seamless cold drawn tubes are used in a wide range of sectors:

Automotive and Transportation: Used in shock absorbers, drive shafts, steering components, and brake systems.

Machinery and Equipment: Vital for hydraulic and pneumatic cylinders, heavy-duty mechanical parts, and precision tools.

Architecture: Ideal for structural components in modern buildings and infrastructure, offering both load-bearing capability and sleek aesthetics.

Energy and Power Generation: Used in heat exchangers, boilers, and pressure equipment where performance under extreme conditions is essential.

Aerospace and Defense: High-strength steel tubes are used in structural frames, engine parts, and critical assemblies where failure is not an option.

TORICH: Precision, Performance, and Professionalism

When it comes to seamless cold drawn tubes, TORICH stands out as a trusted global manufacturer and supplier with years of experience in producing high-quality steel tubing. TORICH is dedicated to delivering products that meet the exacting standards of engineering, durability, and efficiency.

Why TORICH?

Complete in-house production: From raw material to finished tube, ensuring full quality control.

Wide size range and materials: Serving everything from standard dimensions to custom-designed tubing.

Global certifications: Products conform to international standards such as ASTM, DIN, EN, JIS, and ISO.

Technical expertise and service: A team of experts that understands both product and application, providing solutions tailored to your needs.

Sustainable practices: TORICH places importance on responsible manufacturing and efficient use of materials.

Conclusion: Strength You Can Design With

In modern engineering and design, the smallest components often carry the greatest responsibility. Seamless cold drawn tubes deliver the strength, precision, and reliability that industries demand, from core machinery to advanced architectural designs.

With partners like TORICH, manufacturers and engineers can be confident they are working with top-tier tubing solutions backed by professional service, consistent quality, and technical know-how.

Whether you're building machinery, infrastructure, or innovation itself—start with a solid foundation. Start with TORICH seamless cold drawn tubes.

Understanding the Benefits of Seamless Cold Drawn Tubes in Manufacturing