As the demand for plastic recycling continues to rise globally, PVC crushing machines play a vital role in turning waste into reusable materials. These machines are an essential component of the recycling process, helping industries reduce environmental impact while enhancing the circular economy.

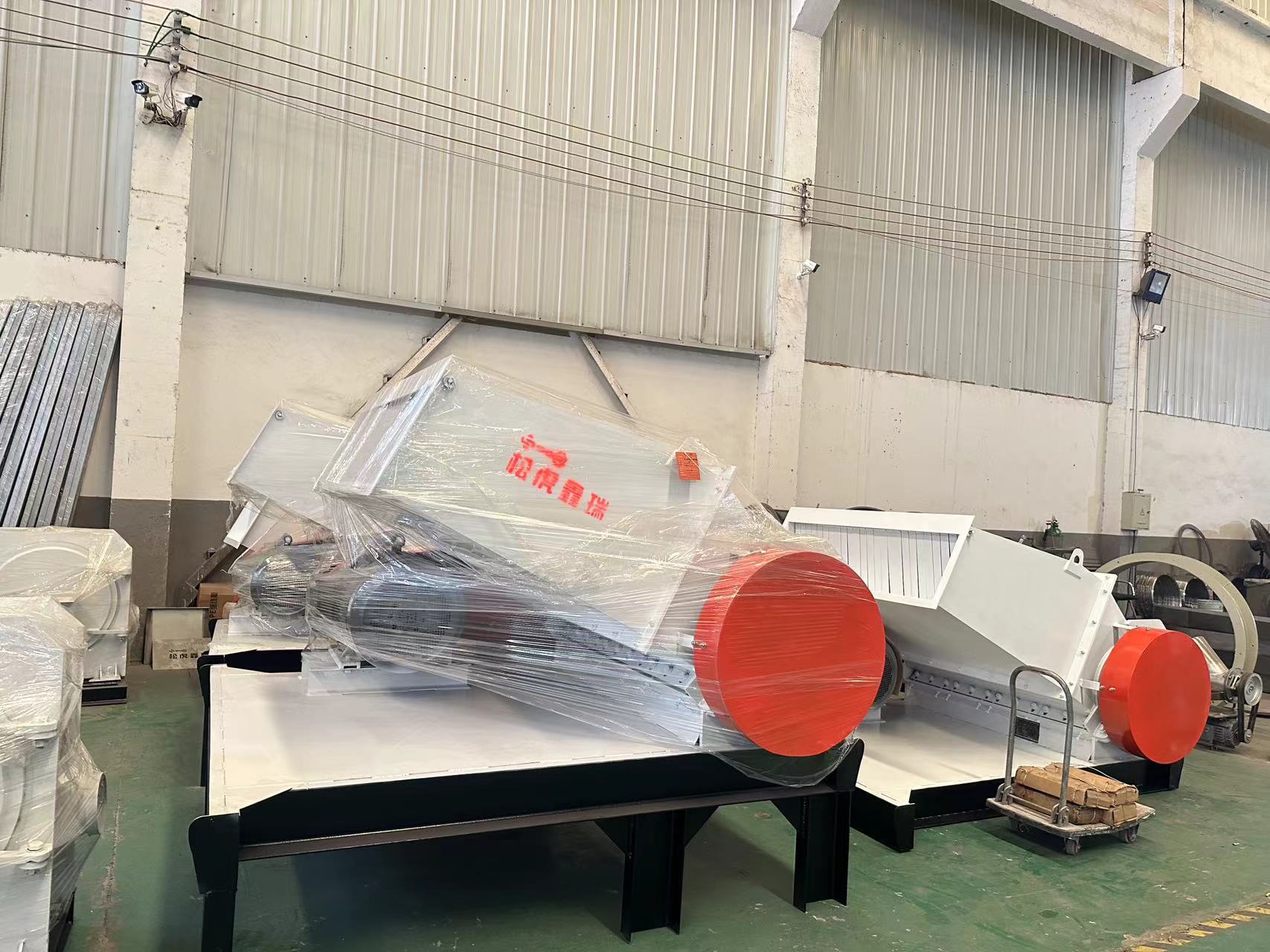

At the forefront of this technology is Songhu Xinrui, a professional manufacturer specializing in PE pulverizers and PVC crushing equipment. With a strong focus on engineering precision, performance stability, and customer-focused solutions, Songhu Xinrui provides advanced equipment that supports efficient and sustainable plastic recycling.

What is a PVC Crushing Machine?

A PVC crushing machine, also known as a PVC granulator or shredder, is a mechanical device designed to break down rigid or soft PVC (polyvinyl chloride) waste into smaller, manageable granules or flakes. These crushed materials are then used as raw material in the production of new plastic products.

Crushing PVC is not as simple as it may seem. PVC has a dense molecular structure and varying degrees of hardness depending on its application (e.g., pipes, window profiles, films), which requires a purpose-built machine with the right design, cutting mechanism, and motor power.

Key Components of a PVC Crusher

Songhu Xinrui's PVC crushing machines are built with a number of core components that work together to ensure efficient and precise size reduction:

1. Feeding Hopper

The entry point for PVC materials, designed to handle large or irregularly shaped items. Some models may include safety interlocks or automatic feed conveyors.

2. Rotor and Cutting Blades

The heart of the machine. The rotor rotates at high speed, equipped with heavy-duty steel blades that shear the PVC material against stationary counter blades. Blade design and spacing are tailored for optimal cutting efficiency and minimal dust generation.

3. Screen Mesh

Located beneath the cutting chamber, the screen ensures that only particles below a certain size exit the machine. Larger pieces are retained in the cutting zone until they are adequately crushed.

4. Motor and Drive System

High-torque motors provide the power necessary to crush tough PVC materials. Songhu Xinrui machines often use energy-efficient motors to reduce operational costs and improve environmental performance.

5. Dust Collection and Noise Control

Advanced models are equipped with dust collectors and soundproof enclosures, making them suitable for indoor industrial use with minimal environmental disturbance.

How the Process Works – Step by Step

Loading: PVC waste is loaded manually or via conveyor into the feeding hopper.

Pre-Crushing (Optional): Larger pieces may be pre-shredded using a twin-shaft shredder.

Crushing: The rotor begins to rotate, and PVC is cut by the action of moving and fixed blades.

Sizing: Crushed pieces pass through the screen mesh; oversized particles remain for further grinding.

Discharge: Final granules are collected via a discharge chute or connected silo for further processing or storage.

Applications of Crushed PVC

Crushed PVC has broad applications across multiple industries:

Pipe manufacturing

Cable insulation

PVC flooring and profiles

Injection molding feedstock

Blended plastic compounds

Songhu Xinrui’s crushing machines ensure clean, uniformly sized output, making them ideal for closed-loop recycling systems and cost-effective reprocessing.

Why Choose Songhu Xinrui?

With years of experience in plastic machinery, Songhu Xinrui has become a trusted supplier for companies seeking reliable and durable recycling equipment. Here’s what sets them apart:

Customized Solutions tailored for various PVC types and production volumes

High-precision blades and rugged rotors for extended service life

Energy-efficient drive systems that reduce operational costs

Comprehensive after-sales support including installation, training, and maintenance

Dual expertise in PE pulverizers and PVC crushers, making them a one-stop solution for plastic recycling lines

Conclusion

Understanding how PVC crushing machines work is essential for any business involved in plastic recycling. These machines not only improve material recovery efficiency but also contribute to sustainable manufacturing practices. With a commitment to quality, innovation, and customer service, Songhu Xinrui stands out as a leading provider of PVC crushing solutions designed for modern industrial needs.

What Is a PE Pulverizer? Applications and Core Functions Explained