In the realm of industrial sheet metal fabrication, efficiency, precision, and cost-effectiveness are often at the forefront of discussions. However, amidst these critical factors, one aspect that cannot be overlooked is the importance of environmental protection. As industries strive to meet the increasing demand for metal components, it is imperative to adopt sustainable practices that minimize environmental impact.

The Environmental Footprint of Sheet Metal Fabrication

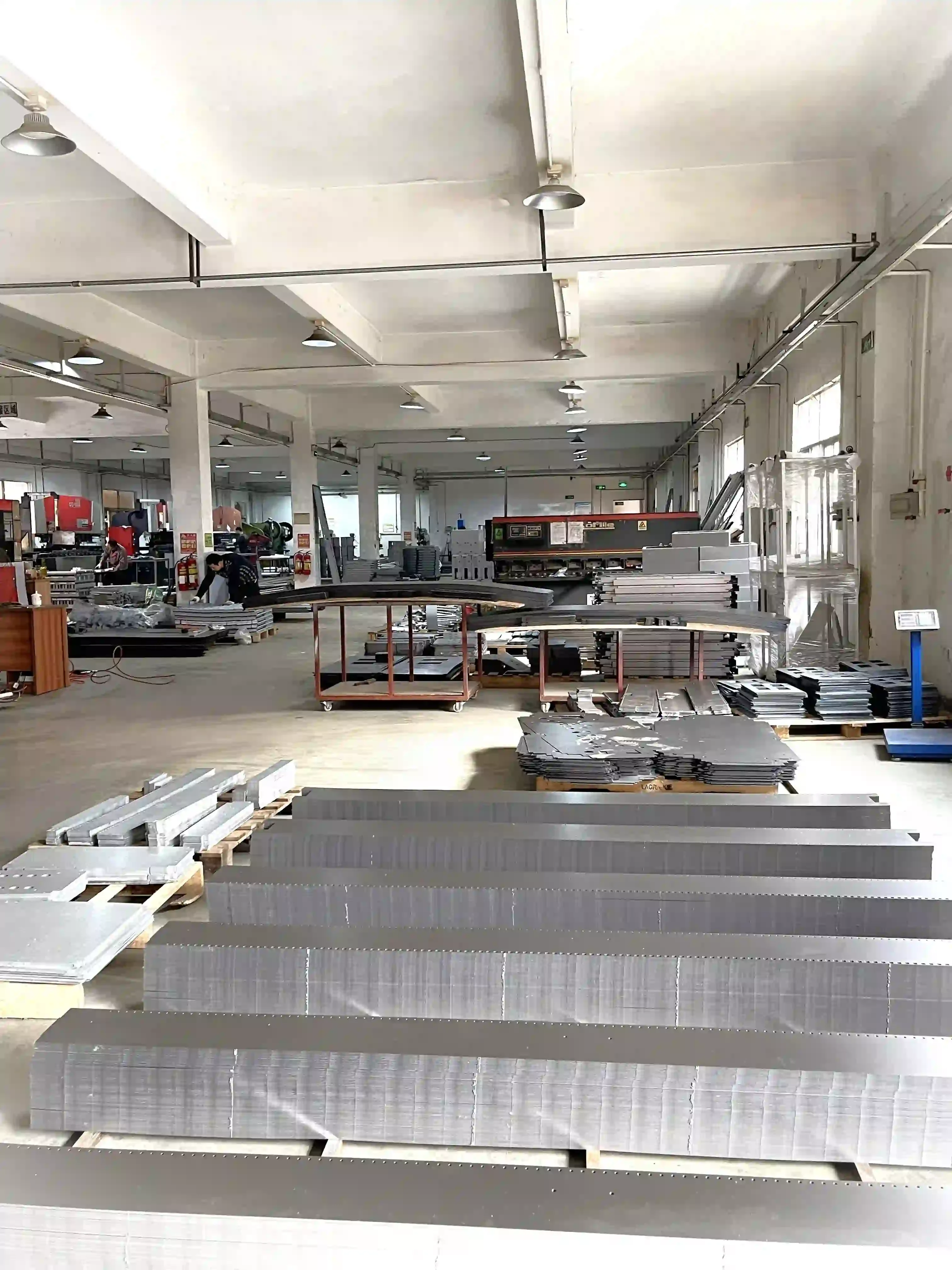

Industrial sheet metal fabrication involves processes such as cutting, bending, and assembling metal sheets into various shapes and sizes. These operations, while essential for manufacturing, can have significant environmental impacts. Energy consumption, waste generation, and emissions are among the primary concerns. The use of high-energy machinery, disposal of scrap metal, and the release of pollutants into the air and water can all contribute to ecological degradation.

Energy Intensity

Fabrication facilities often rely on energy-intensive machinery, leading to high carbon footprints. Electricity consumption for power tools, welding equipment, and HVAC systems can be substantial.

Waste Production

Sheet metal fabrication generates significant amounts of scrap material, which, if not properly managed, can end up in landfills, where it takes centuries to decompose.

Pollution Emissions

Processes like welding and cutting can release harmful emissions, including particulate matter, volatile organic compounds (VOCs), and oxides of nitrogen, all of which can contribute to air pollution and respiratory health issues.

Adopting Sustainable Practices

To mitigate these environmental impacts, industrial sheet metal Changhong Precision must embrace sustainable practices. Here are some key strategies:

Energy Efficiency

Upgrading to Energy-Efficient Machinery: Investing in machinery that consumes less energy can significantly reduce operational costs and carbon emissions. Look for equipment with high energy-efficiency ratings and consider incorporating smart technologies that optimize energy use.

Implementing Renewable Energy Solutions: Incorporating renewable energy sources such as solar panels or wind turbines can further decrease reliance on fossil fuels.

Waste Reduction and Recycling

Scrap Metal Recycling: Implementing robust recycling programs for scrap metal can significantly reduce waste. Scrap metal is a valuable resource that can be melted down and reused, conserving raw materials and energy.

Design for Recycling: Collaborating with designers to create products that are easier to disassemble and recycle at the end of their lifecycle can enhance sustainability.

Emission Control

Advanced Filtration Systems: Installing high-efficiency particulate air (HEPA) filters and other advanced filtration technologies can capture harmful emissions before they are released into the atmosphere.

Alternative Welding Techniques: Exploring alternative welding methods, such as laser welding or friction stir welding, which produce fewer emissions, can be beneficial.

The Business Case for Environmental Protection

Adopting sustainable practices in industrial sheet metal fabrication is not just a moral imperative; it also offers significant business benefits.

Cost Savings

Energy efficiency measures and waste reduction initiatives can lead to substantial cost savings. Reduced energy consumption and lower waste disposal costs can improve profitability.

Enhanced Brand Reputation

Consumers and stakeholders are increasingly looking for companies that prioritize environmental responsibility. By adopting sustainable practices, Changhong Precision can enhance their brand reputation and attract a wider customer base.

Regulatory Compliance

Environmental regulations are becoming stricter globally. By proactively adopting sustainable practices, companies can ensure compliance and avoid potential penalties.

Innovation and Competitive Edge

Investing in sustainable technologies and processes can foster innovation, leading to the development of new products and services that differentiate the company in the competitive market.

Conclusion

The importance of environmental protection in industrial sheet metal fabrication cannot be overstated. By embracing sustainable practices, companies can minimize their environmental footprint, reduce costs, enhance their brand reputation, and stay ahead of regulatory requirements. The journey towards sustainability requires a commitment to continuous improvement, collaboration with stakeholders, and a willingness to innovate. As the world increasingly recognizes the urgency of environmental challenges, Changhong Precision have an opportunity to lead by example, driving change and fostering a more sustainable future.